Acid washing is distinct from acid etching.

Washing is an acid cleaning process – only undertaken if requested.

Creates a light smooth matte finish, and a more consistent control over colour.

Etched

Etching results in a fine, sand-textured surface that resembles limestone or sandstone and where the cement paste and sand are the predominant elements visible on the surface.

A very good off-form surface finish with a minimum of voids – enabled by the high quality moulds that are used to manufacture precast – is required to successfully apply this finish.

An etched finish is achieved in the precast factory by washing the element with an acid solution and then scrubbing the surface to remove the outer skin, about a week after the element is removed from the mould.

The advanced manufacturing techniques which are engaged in precast concrete manufacture ensure that chloride penetration to the reinforcement is not a risk in etched precast elements.

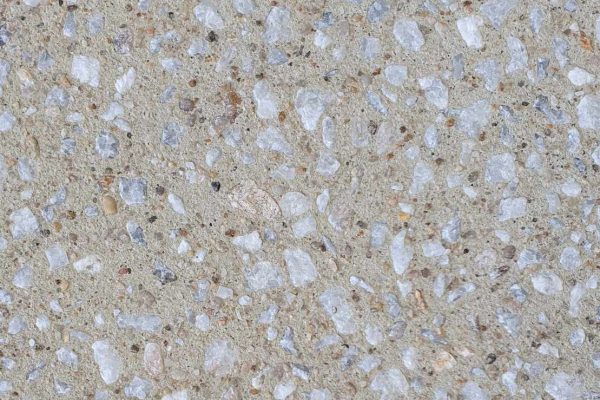

Blasted

A grit (or sand) blasted finish is typically a rougher and deeper-textured finish than an etched finish. With this finish, the surface layer of concrete is removed to expose the aggregate (stone) in the concrete mix.

The depth of the blasting can be varied to allow a smooth to coarse texture. The aggregate selection, as well as the matrix colour, has a significant effect on the final appearance.

The finish is achieved using a technique using compressed air to propel various particles (e.g. granulated furnace slag, aluminium oxide, glass beads) onto the concrete surface. The process is also referred to bead blasting where larger beads are used.

Exposed Aggregate

An exposed aggregate finish removes the top layer of the concrete matrix to expose the top surface of the aggregates in the concrete mix.

Chemical retarders are often applied to the surface to etch away the concrete matrix without sacrificing the aggregate.

Alternatively a water washing technique may be used. It is often used in conjunction with other finishes.

Note

Concrete is made from natural raw material, so while we take care to ensure you achieve the desired outcome, expect aggregate and colour variations and imperfections in precast.

Photos and samples are an indication only and can vary in colour, shape and texture, there is no guarantee that your precast project will look exactly like the sample that you have viewed.

Architects and builders, please be aware that minor patching/repairs may be required due to handling, transportation and installation- these are likely to be noticeable.